plastic injection molding automotive parts

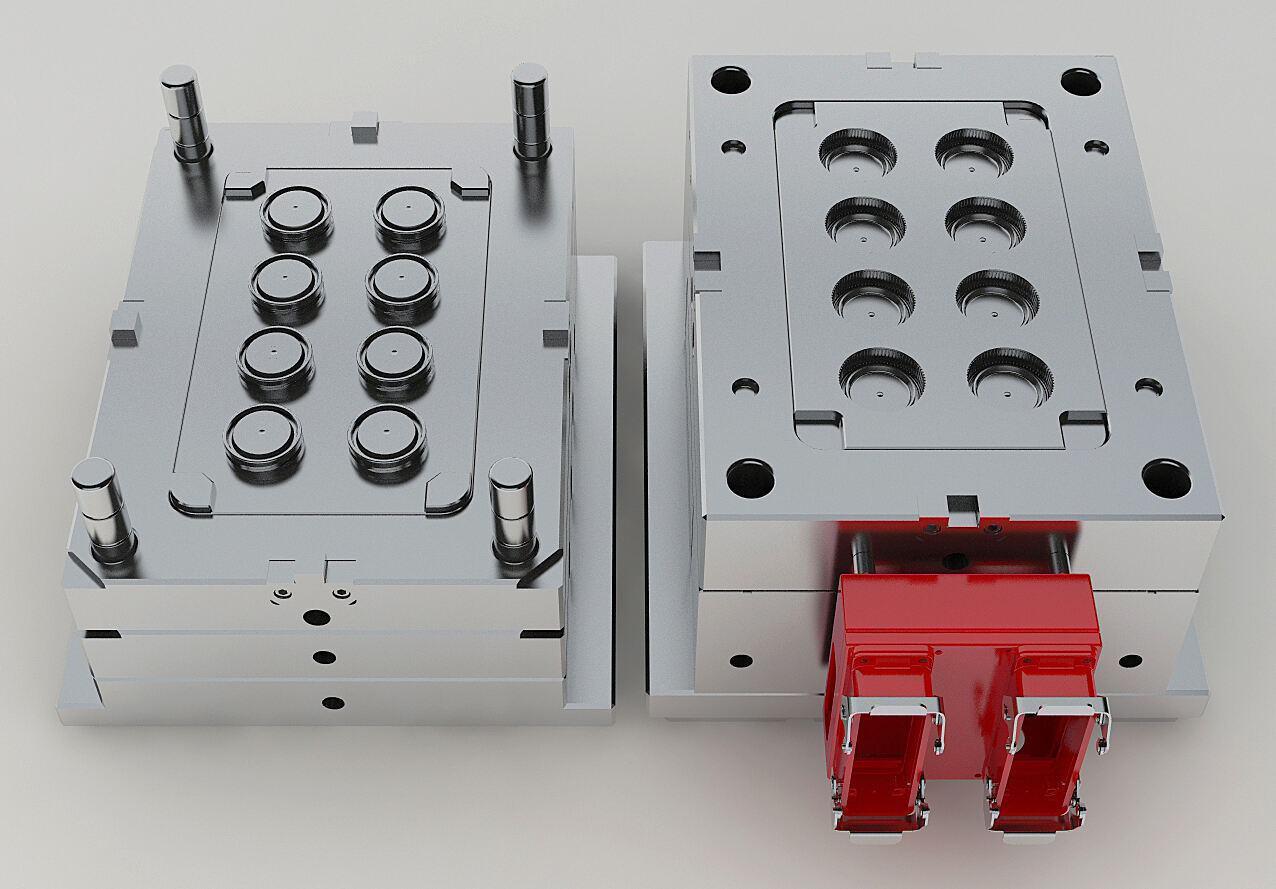

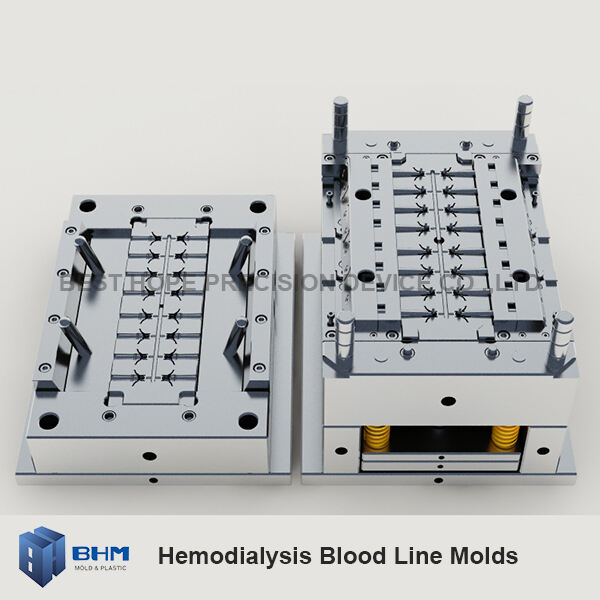

Plastic injection molding automotive parts represent a cornerstone of modern vehicle manufacturing, offering a sophisticated blend of durability, precision, and cost-effectiveness. This manufacturing process involves injecting molten plastic material into carefully designed molds under high pressure, creating complex automotive components with exceptional accuracy. These parts serve various critical functions in vehicles, from interior components like dashboard panels and door handles to exterior elements such as bumpers and grilles. The technology employs advanced thermoplastic materials that meet stringent automotive industry standards for safety, durability, and performance. The process allows for the production of parts with intricate geometries and consistent quality while maintaining tight tolerances. Modern injection molding systems utilize computer-controlled parameters to ensure precise material flow, temperature control, and cooling rates, resulting in superior part quality and reliability. These automotive parts are engineered to withstand diverse environmental conditions, resist chemical exposure, and maintain structural integrity throughout the vehicle's lifecycle. The versatility of this manufacturing method enables the production of both small, detailed components and large structural parts, making it indispensable in contemporary automotive manufacturing.